Glossary of Parts

Quick Connects

Quick connects are to quickly disconnect the keyboard without needing to pull the USB lead from either the keyboard, or PC, but mainly, they just offer a cool look and customisation options for your cable in order to match your custom cable to your keyboard, keycaps, or indeed anything else. Also, if you own more than one Kool Keys cable, you can mix and match the cables to allow the device end of one to be used with the host end of another. This is only advisable with cables bought from Kool Keys however, as not all cable manufacturers use the same wiring protocol.

Below (and in the image left) are the three main connectors we regularly use. Others are available, so if you require something else, please get in touch to see if we can help you.

The GX16 is regarded as the OG connector that was the first to be used for custom keyboard cables. It's bulky, robust and has an industrial look. It is well suited to larger, hefty keyboards and can accept up to 7mm cable diameter. The two halves connect with a screw locking collar, so it's the least practical, but let's be honest, we love custom cables for their aesthetics, not practicality :) They are nickel plated cast copper in construction.

The Lemo style connectors are perhaps the most popular, and they are beautifully made connectors machined from brass, and look stunning either in their factory electro-plating, Cerakoted, or even in their raw state, either polished or with patina. They are push pull connectors and come in a variety of sizes, but for practical keyboard use, 0B and 1B are the most useful. 1B can accept up to 7mm cable and 0B up to 4.5mm cable. The 0B is not suitable for double sleeving due to its size. (see Sleeving section below)

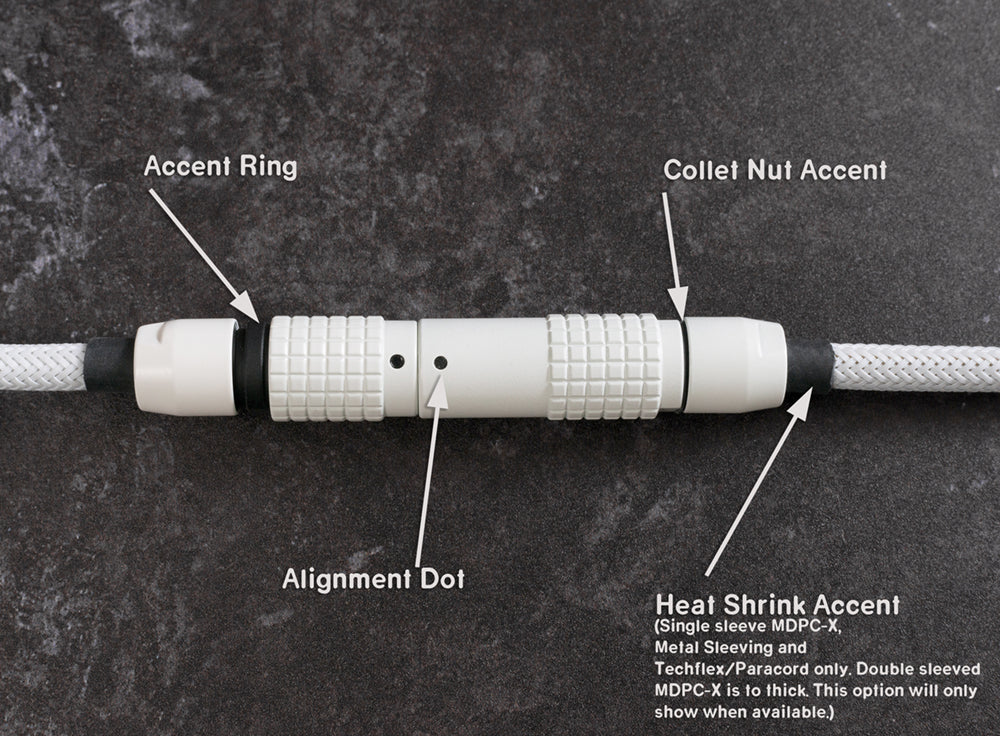

Quick Connect Custom Options

There are a range of options you can choose for your quick connectors (if you order a cable using them). This includes Cerakote in a range of colours; Having different parts of the connector finished in different colour Cerakote; Heatshrink colour accents, latch sleeve colour accents (accent ring), and alignment dot colour customisation. We can also offer real patina if you choose Lemo style connectors as these are manufactured from raw brass.

Some of these options will automatically be removed from the configurator if you choose a connector options that doesn't support it.

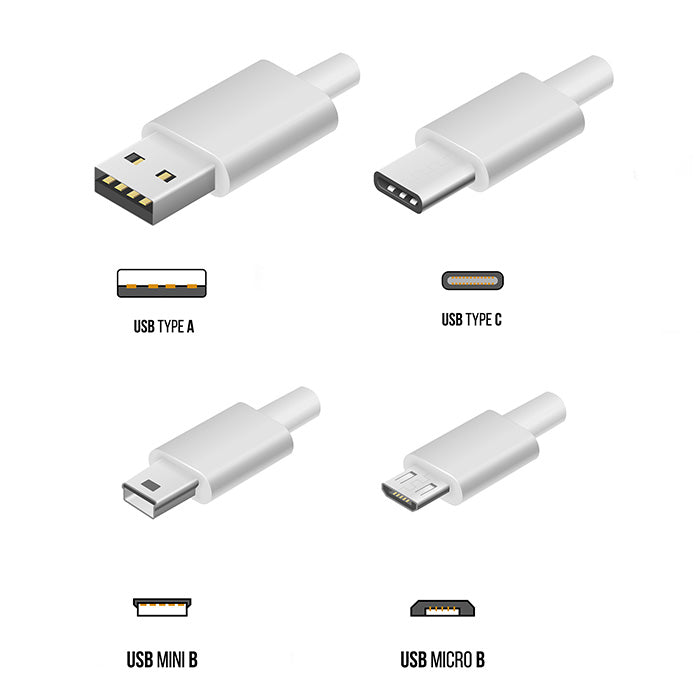

USB Connector Type

For the host (computer) side, we supply both type A and Type C USB connectors.

For the device (keyboard) side, we supply Type C, Mini B and Micro B USB connectors.

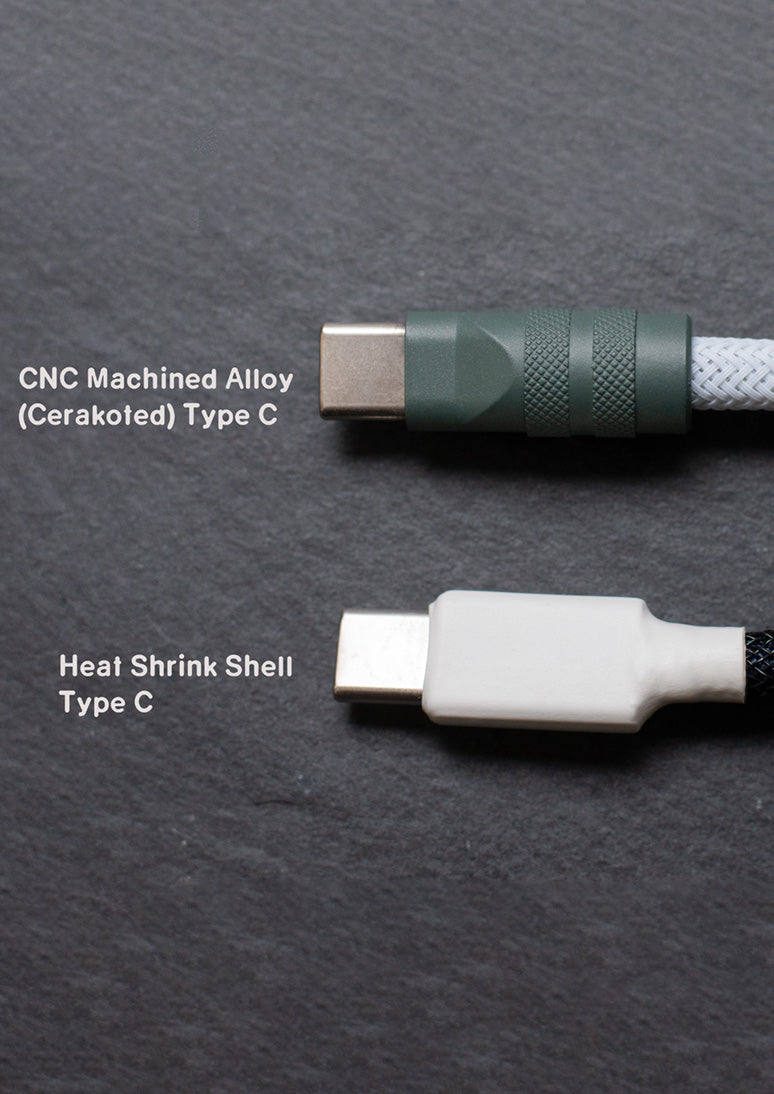

USB Housings

On all our Pro and Premium range cables, Kool Keys only uses CNC alloy or copper USB connectors, as these can be customised with Cerakote to match the chosen quick connects. All our CNC connectors are filled with a tough two part resin to form a solid state connector that will last a lifetime. No other cable maker does this.

While we can fit CNC connectors to the PC end of the cable, we don't do this by default, as these are usually hidden behind the computer, and rarely seen, although you can request this as a custom order. We can keep costs down to a minimum by instead using high quality metal USB shells coated with Techflex Polyolefin heat shrink. If you do require a CNC connector for the PC end of the cable, you can configure this using our cable configurator. If the option is not present, it means that option is out of stock temporarily. Items rarely asked for may not be quickly restocked, so drop us a line if there's anything you need that you don't see.

We also offer heat shrink USB connectors for the device (keyboard) end as well if you wish to reduce costs further, or if fitment issues using CNC connectors are a problem such as with boards like the Unikorn or most Mode boards. Note: We cannot offer the life-time warranty on cables that use heat shrink type C connectors. Instead these cables will have a 5 year warranty.

Cable

We use a variety of quality cable for our products, and the exact cable used will depend on the choices you make in the configurator. For example choosing a single sleeve of MDPC-X with a 1B connector will use 22 or 26AWG cable with an outside diameter of 4mm or 4.1mm respectively. Choosing a double layer of MDPC-X will use 26AWG cable, or 24 (power)/28 (data)AWG cable with an outside diameter of 3.5mm. The total diameter of the finished cable will therefore remain approximately the same when built.

All cable if fully shielded and USB2.0 compliant unless otherwise stated. Silicon type cables my not be shielded however. Each product's description will list what kind of USB cable is used.

Sleeving

Cable sleeving is an important part of any custom keyboard cable, as it not only makes the cable more appealing due to the range of types and colours available, but it also makes the cable more durable, thicker and more likely to sit straight for that perfectly managed look. We offer a range of sleeving for different purposes. The main type we use is MDPC-X. This is German manufactured PET sleeving with a very close weave that covers a range of cable sizes perfectly. The XTC variant offers an even tighter weave suitable for single sleeving in a single colour without showing the underlying cable as obviously.

We also offer the more traditional 2 layer process using paracord as a base layer, with Techflex as a top layer. Techflex is a US made, open weave PET sleeving that shows the underlying cable more clearly. As a result you can combine one colour for the paracord, and and another for the Techflex to give a 'perceived' third colour.

This principle is also true to a lesser extent for MDPC-X by using the XTC version as a base layer, and the normal version for the top layer, as this will also allow the base layer to show through, but it's far more subtle and only really works with a vivid base layer colour. If a combination of MDPC-X doesn't work well when tested, we will e-mail you using the same address you used to place the order within 48 hours, so please check your mail... and spam folder regularly.

All these options have an affect on the total cable diameter, so depending upon the options you choose in the "Design Your Own" configurator, we will select an appropriate diameter USB2.0 compliant wire as the base for you.

The third option commonly used is metal sleeving. We only use Techflex genuine metal sleeving, and you can choose between copper, brass and stainless steel. All metal sleeved cables will use a base layer of paracord of a complementary colour. This is to ensure the there is no binding or abrasion between the metal sleeving and the plastic outer cable jacket.

0B connectors will only have the single layer sleeving option available, and will always use either 26 or 28AWG cable with a 3.5mm outside diameter and total sleeved diameter of 4.4mm.

All single sleeve options will use MDPC-X XTC.

A suitable diameter USB compliant cable will be chosen depending on your chosen connector type and size.

The connector choice will also affect what sleeving options you can choose and the configurator will automatically add or remove options depending upon the connector choice you make to prevent you from ordering a cable combination that is not possible.

What is Cerakote?

Cerakote is a unique, thin film ceramic coating manufactured by NIC Industries inc. in the United States. It is corrosion, abrasion and chemical resistant. It's also tough and will protect the connectors. However, Cerakote is only as strong as the material it is applied to, so it won't make your connectors bullet proof, but unless you bang the edge of a connector against another metal object, you are unlikely to damage the finish. Cerakote's strong point though, is its resistance to abrasion and scratching, so sliding it across surfaces like your desk will not mark it.

Applied well, it is nominally 1 mil thick (0.02mm), and shows the underlying detail like no other coating can. When applied well, it looks as if the actual metal is the chosen colour instead of looking like it is painted. While some Cerakote colours are thicker than others, the finish is capable of being as smooth as the underlying surface without adding any additional texture. No other coating either looks like it, or performs like it.

Important Information Regarding Coils

How Your Coiled Cable Is Packaged (see video below)

To keep your coil tight and straight during shipping, and to also make it easier to fit inside our packaging, we ship coils over-wound by half a turn or 180 degrees. Please pay attention to the below video on how to correctly orient and place your coiled cable to ensure it gives the intended aesthetic appearance. You see coiled cables that have uneven coil sizes at one end of the cable all the time. While these may just be inferior cables, the likely cause it under-winding the cable.

Coiled Cables and RGB and Gaming Boards

Some gaming boards, and some boards with lots of RGB will demand a lot of power, and cable length therefore becomes an issue. Consider overall length when choosing a coiled cable if you own such a keyboard. A 6 inch coil can use just short of 2 metres of cable, so when you add a 2 metre host side lead to that, you're totalling a 4 metre, or a 13ft cable. If in doubt, use a very short coil, or select a straight, non-coiled cable.

Coil Handling and Installation

Notes On Coils Using Metal Sleeving

While it is possible to make coils sleeved in copper, brass and stainless steel, there are issues you need to be aware of. Normally, coils are made by forming the coil on a rod, held in place, and oven baked. This aligns the plastic's polymers and forms a coil "memory". Normally the sleeving, being plastic, forms part of this process, so the sleeving and wire in combination are working together to keep the coil shape.

With metal sleeving, while the internal wiring insulation will forming the same memory affect, the outer metal sleeving will not. In fact, the metal sleeving will be doing the opposite: Metal sleeving wants to stay where you put it, so the two are fighting one another. Metal sleeved coils are perfectly possible, but as a result of the above, they are quite fragile, and any stretching will result in the coils wanting to stay in the position they are stretched to. To some extent, this can be corrected by pressing the coils back together again, or winding them tight again. However, Kool Keys will not warranty a metal sleeved coil to keep it's shape at all although this does not affect the other conditions of warranty (see the warranty section here), and all metal sleeved coils should be handled with extreme care. They are to be placed on the desk carefully and not stretched at all. There will be a clear warning and a care document re: this placed in every order that contains a metal sleeved coil, and all customers who order one will be advised as to the fragility of such a cable.

This is only relevant to coiled cables. Straight cables using metal sleeving obviously do not suffer these limitations, although they will still have a tendency to retain any shape you place them in, but this can be an advantage for cable management with a straight cable.